Products

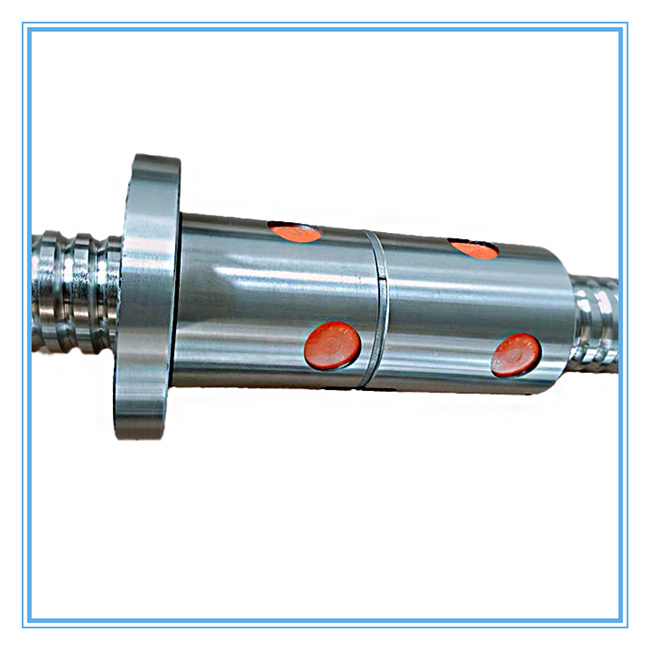

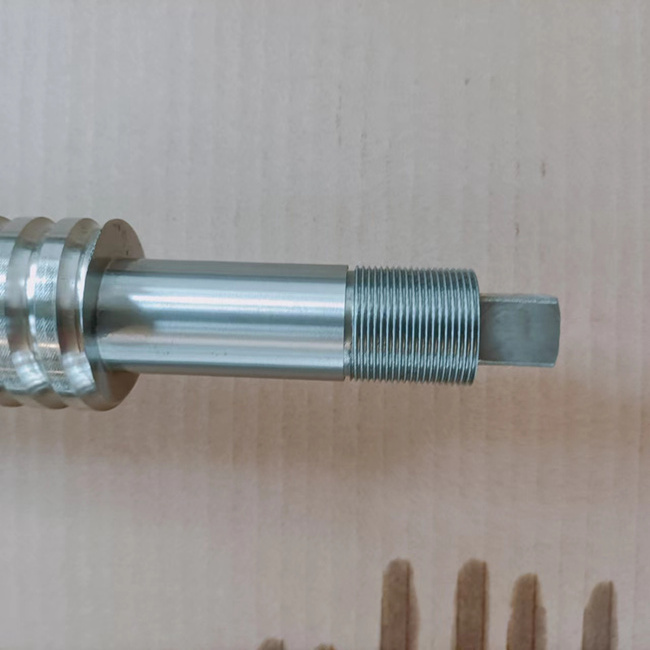

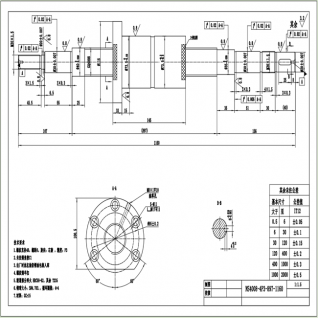

Heavy duty ball screw with single double nut according to client dawings requirements

1. Process :C5 ,C7 precision --rolling , C5,C3 precision -grinding

2. Manufacturing:high precision grinding type

3. length :100-3000mm, or processing according to customer requirements

4. Quality :customized high quality

5. Application:Milling and boring machine, machining center ,grinding machine

The heavy duty ball screw is not installed correctly, the lubrication of the feed drive is poor, the material quality is problematic, the screw support bearing gland is not properly pressed, the heavy duty ball screw is damaged, the screw support bearing may break, the load is too large,and the axial preload is too small, which makes the transmission gap of the feed drive chain too large, resulting in the axial runout of the screw drive, and the problem of movement will occur.

The movement of the heavy duty ball screw means that in the screw drive system,when the load is greater than the accuracy level, the heavy duty ball screw will lose its normal motion accuracy, swing back and forth, and even fail to transmit normally.

As a result, loud noises and vibrations will be generated, which seriously affects the working efficiency and stability of the machine.

When the heavy duty ball screw moves, it is necessary to check whether the back cap of the support bearing is locked, whether the support bearing has been worn and failed

|

Precision |

C3 precision, C5 precision , C7 precision |

|

Material |

GCR15 material, brass matrerial |

|

Application |

cnc, mechinical arm, machint tool, industrial aquipment |

|

Moq |

1set or more |

|

Dlivery time |

5-40days, Custom goods:30-40days |

|

Packing detaild |

plastic bag+wooden box |

|

Our Services |

Custom ball screw with free design drawings |

Finished product

Dimension re-measurement