Products

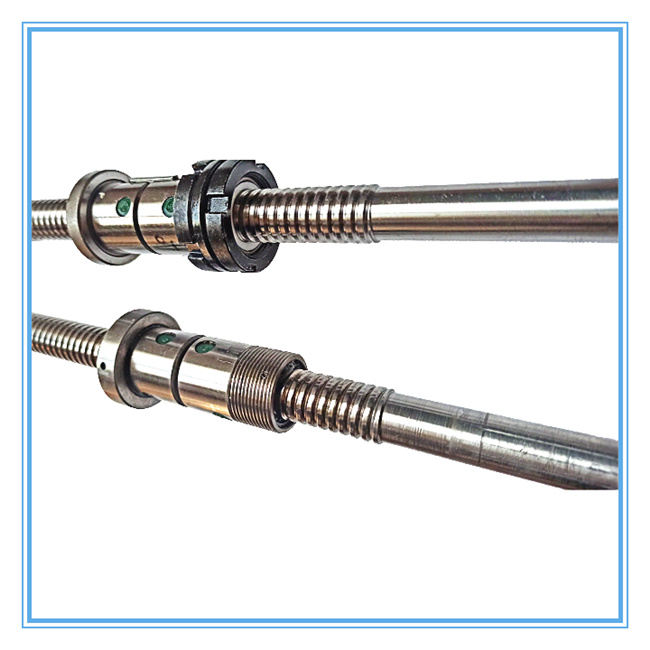

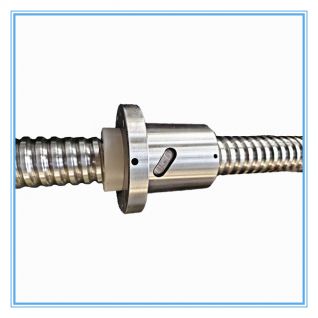

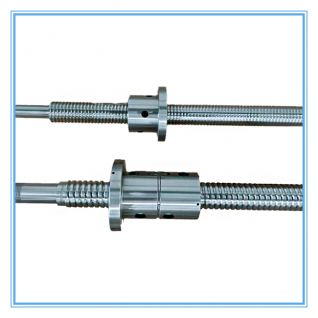

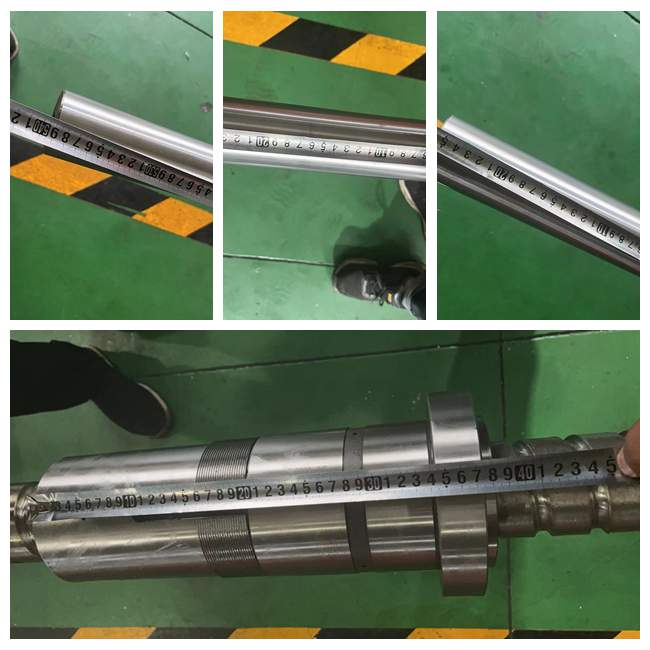

Customized non-standard large size nut ball screw C3 C5 C7 precision CNC ball screw

1. Processing :Ground processing large type ball screw

2. Ball screw material :Gcr15 steel material(HRC58-62)

3. Guarantee precision :C3 C5 precision

4. Features :1. high precision .C5 2. Low noise

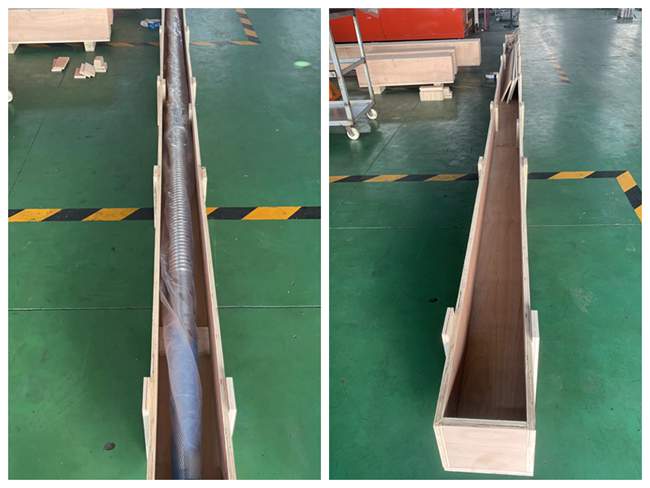

5. Length:any length request according to customer;s drawing

6. Service:will provide final processing drawing

Problems and solutions for return error of nut ball screw,

Analysis of causes of return error

1. Manufacturing process factors

a. Insufficient processing accuracy

During the manufacturing process of nut ball screw, if the processing accuracy is not high enough, it will lead to problems such as large surface roughness and large shape error of the screw, thus affecting its motion accuracy and stability.

b. Improper material selection

The material of the ball screw has a great influence on its performance and service life. If the selected material is of poor quality or not suitable for the use conditions, it will cause problems such as easy wear and deformation of the screw, and then cause return error.

c. Improper heat treatment process

During the heat treatment process of the 180.5mm , if the temperature, time and other parameters are not properly controlled, it will lead to problems such as unstable internal structure and uneven hardness of the screw, thus affecting its accuracy and stability

Processing details

Packaging